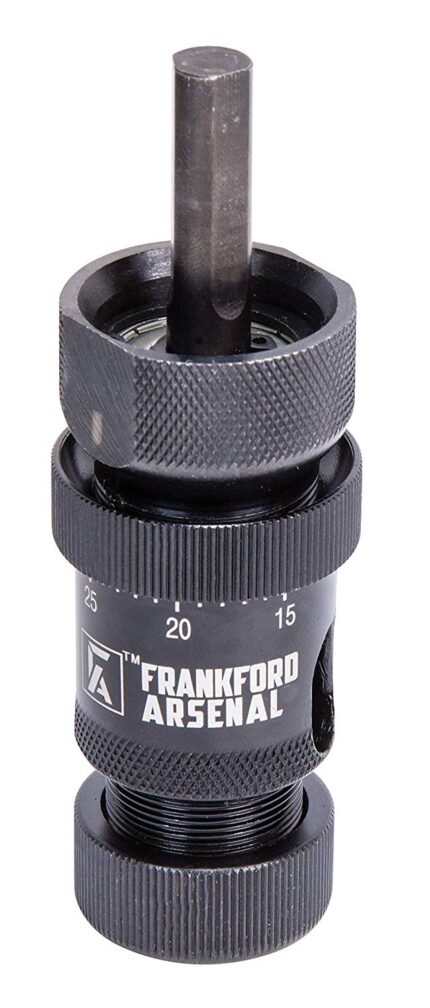

Designed by reloaders for reloaders, the Frankford Arsenal X-10 is a 10 station automatic indexing reloading press purpose built from the ground up to be the ultimate progressive reloading press. At its core, the X-10 features rigid steel construction, multiple ball bearings, and a proprietary 10 station, gear driven, rotating shell plate which all combine to virtually eliminate powder spillage and bullet tipping. The X-10 offers innovative improvements like dual de-capping stations to prevent primer drawback, in-line primer pocket swaging capability (for both small and large primers), and the ability to run powder check and case trimming dies. The X-10 includes a case actuated powder measure with a positive reset that guarantees you’ll never have to worry about squib loads resulting from a sticking powder measure. When it’s time to swap calibers, the X-10’s innovative design allows the user the ability to quickly and easily swap out tool heads and shell plates to reload anything from 9mm to .308 length cartridges. The X-10 goes further and offers refined details like a roller handle, integrated LED light, and spring-loaded case locator buttons, which allow easy one-handed case feeding and lever operation, making the X-10 exceptionally smooth and easy to operate. Includes Frankford Arsenal Case Feeder.The X-10 is the ultimate solution for progressive reloading. Specifications for Frankford Arsenal X-10 Progressive Press w/Case Feeder: Manufacturer: Frankford Arsenal Cartridge: Universal Fabric/Material: Steel Condition: New Color: Black Package Contents: Frankford Arsenal X-10 Progressive Press w/Case Feeder

peashooter –

Very pleasant experience with Frankford Arsenal and Optics Planet. Arrived sooner than expected and a great price as well. Quality is very good- everything fits and feels substantial and well made

Sam –

Take your time and set up properly and it can crank out 100s of rounds quickly. Be aware that the first batch of these shipped to OP and Midway did not come with upgraded bearings. FA customer service confirmed this and shipped out replacement parts quickly.

Al –

I am absolutely stunned! I have been reloading ammo for 45 years. I have every kind of single-station press there is and multi-stage press. I have three Dillon presses, a RL550B, XL650 and XL750. The Franklin Arsenal X-10 is the finest press I have ever gotten my hands on and not just for the money. It is built like a Swiss tank. It is smooth to operate without any slop. The parts fit precisely together. The fit and finish are just fantastic. The only downside is the amount of grease they pack it in. It's a pain to remove but that is just fine. It shows they care even about that.I have never used a Dillon RL1100 or a Mark 7 but this is surely in that class.The only thing I wish they would have done was to make the case-activated powder measure also expand the case mouth, as the Dillon powder measures do. The powder measure itself is awesome but if it could use the Dillon-style powder through expander funnels…that would be amazing. It would really help with bullet tipping when using a Mr Bullet Feeder and not waste a die station by having to use a Lyman M-die. also, the powder funnels available are specifically designed to work with the Mr Bullet Feeder. We could use a 223 expander funnel too by the way.I don't have the bullet feeder yet so I'm using my Mt Bullet Feeder, which is not ideal. The F/A bullet feeder integrates into the top of the machine die holder. I hope it works as well as the rest of the machine.I would not hesitate to buy another X-10. I don't know how they can improve the basic machine itself but I look forward to using mine.

TomOH –

I have been reloading for about 25 years and used primarily RCBS Rock Chucker and a few LEE Loadmaster progressive presses. They worked, but now my son joined me at the range and we go through way more ammo than in the past, and while I did not mind replacing parts and tuning the LEE presses, the throughput just wasn't what I was looking for. The question was either getting FA X-10 or a Dillon. I liked the 10 stages and that is comes with a case feeder out of the box, so ultimately less expensive than the Dillon. Ordered the X-10 and ran it for about a week now.- It comes in pieces and requires assembly. Fun and makes you learn, how it works.- There are a few items that need adjustment (powder measure, case feeder feeding into shell plate, crimp remover and primer seating pin)- It so far worked really well with zero problems – I get to about 600 rounds/hr in 9mm with manual bullet feeding.- Almost everything you need (besides components, shell plate) is included to get you started- The paint chips off in several areas and Frankford Arsenal does not care "cosmetic, not functional, no warranty". So rust prevention/protection is not a function of the paint. Utterly pathetic, poorest quality control (and a problem they are aware of!!!) – well, you get what you pay for.- Shell plates need to be ordered extra and are about $65 each.- Changing calibers is a lot of work and unscrewing almost everything – not sure, if that is worth it.Bottom line, a huge step up from the Loadmasters, and I would buy it again. The lack of built quality and pathetic support/warranty is something to consider though!

Karma –

It’s built like a tank. It weighs 100lbs. And it’s 4feet tall with the case feeder. The frame is spring steel. What swords are made of. The tool head is heavy but it just glides up and down when set correctly. The lever will free fall if I let it. I can move it with my pinky. The case feeder sounds more like jingling change in your pocket instead of as loud as brass in a tumbler with no media. It has built in led lights so you can see every station. It comes with one die for swaging and the powder charge. The dial is a precision style dial, but different powders will throw different. But it’s within .1 of your target. You will need 6 3/8 bolts to mount it. If you sit, mount it about waist high. If you stand mount it a little higher so you won’t have to reach for the handle. It will intimidate you un boxing it. Relax and spend the first night cleaning all the grease off. It’s gonna take more than a paper towel and a a tip. Once you have cleaned it well you will understand better what all is going on with it. Don’t put it together until you get your shell plate. It’s not as difficult as you will want to make it. If you complete a step and it stops feeling effortless, stop and look at what you just did and you will find where any bind is. 10 stations seems like a lot, but it fills out easy enough. Take a 4die set and add a powder checker or lock out sue and a hold down die and you can run better than factory ammo. It swages and primes with low primer alarm so you don’t charge cases with a hole in the bottom. The bullet feeder isn’t out yet. But it’s coming. Be sure to have your old press put up before you whip this monster. This is like the press your wife said not to worry about. You will be able to run a batch of 500 before you can without your arm getting tired. Easily make 1,000 in a few hours and be at least to mfg standards if not better.

xkno13 –

Update from my previous review. Figured out that the bearing crushing issue in cam is from putting the rear hold down nut flush with the bottom of the press. (The one near the powder drop) If you leave a 2mm gap after installing all your dies and running a cartridge fully thru the press, no bearing issues. No issues at all. **NOTE-Frankford Arsenal please take note and update your installation instructions.With that said, I would now recommend this press. I am using Winchester small rifle primers and this seems to be the manufacturer which works great. Still need to try federal. Either way these have been the best 223 rounds I have ever made. Cannot comment on large primers.